- info@zhongyi-ink.com

- Qunfu Industrial park,Gangkou,Zhongshan City,Guangdong, China.

Substrate

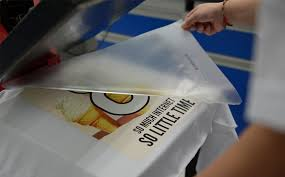

Tongue label of sports shoes, bottom label, various trademarks, clothing offset hot stamping processing

Usage

Sports shoes tongue label/bottom logo/all kinds of logos/all kinds of clothing offset hot stamping

Characteristics

Super washable, anti-wet and dry rub, anti-yellowing; Soft touching, simple printing and excellent elasticity

Heat transfer ink is an ink formulation explicitly designed for heat transfer printing processes. Unlike traditional inks that are absorbed into a substrate, heat transfer ink adheres to a transfer medium and is later bonded to the final surface using heat and pressure.

Depending on the formulation and application, there are two main types:

The WG-TH Water-Based Hot Stamping Ink is designed for high-performance hot stamping applications, providing durability and flexibility for various textiles and labels.

The core technology behind heat transfer water-based ink lies in its specialized resin system, which ensures pigments are evenly dispersed in a water-based solution. When printed onto heat transfer film and cured, the ink forms a high-adhesion print layer. During the heat transfer process, the ink layer bonds seamlessly with fabrics, leather, and other materials under high temperatures and pressure, resulting in sharp, vibrant, and durable prints.

This innovation is driven by high-performance polymer resins, stable pigment dispersion, and fast curing properties, making water-based heat transfer ink a sustainable and high-quality printing solution.

One of the biggest advantages of heat transfer water-based ink is its wide compatibility across various substrates, including:

The secret lies in its advanced polymer adhesion technology, which allows the ink to either penetrate fabric fibers or adhere strongly to surface coatings. When exposed to high heat and pressure, the ink bonds permanently, ensuring long-lasting designs that won’t crack, fade, or peel.

For high-stretch fabrics, water-based heat transfer ink can be formulated with elasticity enhancers, preventing cracks even when the material is stretched.

As demand for customized printing and eco-friendly production grows, heat transfer ink is becoming a go-to solution for various industries:

Apparel Industry

Shoes & Accessories

Electronics & Hard Surface Printing

Specialty Printing

Different applications require different durability levels from heat transfer ink. For instance, garment prints must withstand multiple washes, footwear prints need high abrasion resistance, and metal prints require UV resistance.

Application | Key Challenges | Recommended Heat Transfer Ink |

T-Shirt Printing | It needs to be wash-resistant, non-fading, and soft | Water-based heat transfer ink, provides flexibility without affecting fabric comfort |

Footwear Printing | High abrasion resistance, prevents cracking | Elastic heat transfer ink, enhancing adhesion for stretchable materials |

Metal Printing | UV resistance, fade-proof, oxidation prevention | Special-coated heat transfer ink, increasing longevity |

We are looking forward to having business with you. Send us your message to us right now.

Qunfu Industrial park,Gangkou,Zhongshan City,Guangdong, China.

0086 18688131293

Copyright © 2024 ZHONGYI INK & PAINT CO.,LTD., All rights reserved.

WhatsApp us